Discover Servo Motor Types: Technical Insights, Tips, and Informative Knowledge

Servo motors are precision-controlled electromechanical devices used to regulate motion in machines, automation, robotics, aerospace, manufacturing, medical equipment, and countless modern applications. They exist to provide precise control over speed, angle, and torque, something traditional motors cannot deliver with the same level of accuracy. As industries continue moving toward advanced automation, digital control systems, and compact high-performance components, servo motors play an expanding and essential role.

The concept of servo control emerged from early feedback systems used in navigation and mechanical automation. Over time, the need for controlled, repeatable, and high-accuracy motion led to the development of multiple servo motor types, each designed to handle unique operating requirements. These variations allow engineers and industries to choose the right motor for robotics, CNC machines, drones, laboratory tools, and many other systems where movement precision is crucial.

Servo motor technology continues to evolve as improvements in electronics, sensors, microcontrollers, and digital communication enhance precision, efficiency, and reliability. Understanding the different servo motor types helps anyone working with automation or machinery select the most suitable option depending on torque demands, motion range, response time, and operating environment.

Importance

Servo motor types matter today because precision motion control has become central to modern machines and systems. They help industries achieve accurate positioning, repeatable performance, and reliable control in applications where small movement differences can significantly impact quality or safety.

Servo motors affect a wide range of users:

-

Engineers, who design systems that require precise rotation or linear movement

-

Manufacturers, who use automated equipment for consistency and high-quality production

-

Researchers and educators, who rely on servo-driven systems in lab equipment and learning environments

-

Robotics developers, who need responsive motors for movement, balance, and coordination

-

Medical device designers, who incorporate servo technology into imaging systems, automation, and surgical tools

Their importance is also tied to the problems they solve:

-

Reduce motion errors

-

Improve manufacturing accuracy

-

Enable flexible automation

-

Increase energy efficiency

-

Allow remote and computer-controlled actuation

-

Enhance safety through controlled movement

-

Support miniaturization and high-density mechanical design

As advanced automation becomes standard across sectors, knowing the distinctions among servo motor types helps ensure better design decisions, smoother operation, and long-term reliability in any technical system.

Recent Updates

Servo motor technology has experienced notable developments over the past year due to advancements in electronics, sensor integration, and industrial automation growth.

In 2024, key improvements included:

-

Smaller, more efficient brushless servo motors for robotics and compact devices

-

Higher-resolution encoders integrated into modern micro-servo systems

-

Smarter digital drive systems offering improved feedback and real-time diagnostics

-

New industrial protocols, such as improved EtherCAT and CAN-based communication options

-

Enhanced thermal-resistant materials supporting heavy-duty continuous operation

In early 2025, trends continued with updated control electronics, faster response algorithms for dynamic robotics, and improved servo drives designed for smarter manufacturing systems. These developments show a steady shift toward high-performance, energy-efficient servo systems optimized for precise workloads in automated environments.

These updates push servo motor types to become more adaptable, accurate, and integrated into diverse applications from drones to industrial automation to consumer robotics.

Laws or Policies

Servo motors themselves are not usually controlled by specific standalone policies, but their use can fall under broader national and industry rules related to safety, operations, and machinery integration. Several areas influence how servo motor types are selected and implemented:

-

Electrical safety standards such as IEC regulations

-

Automation and machine safety requirements, including emergency stops and controlled movement

-

Energy efficiency guidelines that encourage optimized motor systems

-

Industrial machinery standards affecting how servo motors are used in factory equipment

-

Environmental compliance rules, ensuring materials and electronic components follow proper guidelines

These policies ensure that servo systems operate safely in workplaces, reduce energy waste, and maintain compliance with national and international engineering standards. When servo motors are integrated into robotics or automation, they also fall under regulations related to workspace safety, electronic equipment design, and precision-critical operations.

Tools and Resources

Several tools and resources help users understand and work with servo motor types effectively:

-

Motor selection calculators that estimate torque, acceleration, and load requirements

-

Encoder analysis tools for determining feedback accuracy

-

Microcontroller platforms such as Arduino and Raspberry Pi for controlling servo motors

-

Simulation software that models servo behavior in automation systems

-

Educational websites and technical glossaries explaining servo terminology and feedback principles

-

Motor tuning applications for adjusting speed curves, angles, and response rates

These tools support students, engineers, robotics hobbyists, and automation professionals in selecting the appropriate servo motor type and integrating it into electrical or mechanical projects.

Types of Servo Motors (Explained in Detail)

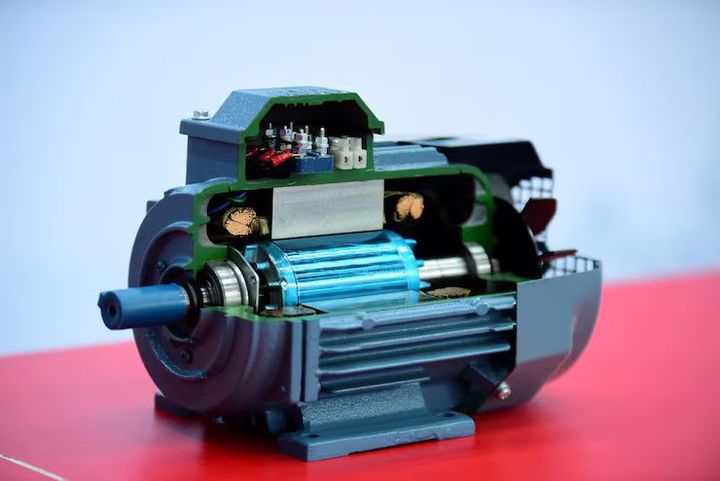

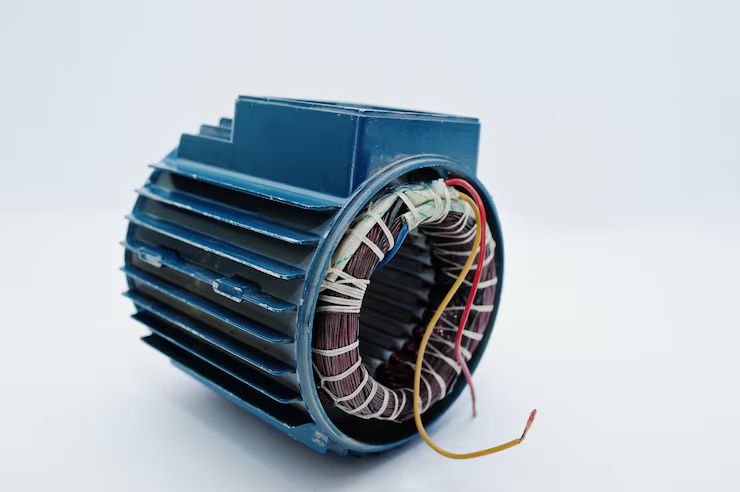

AC Servo Motors

AC servo motors are designed for heavy-duty industrial tasks requiring high torque, stable speed, and continuous operation. They offer excellent performance, respond well to high-speed commands, and remain stable under large loads. Because they use AC power, they integrate easily into industrial drive systems.

DC Servo Motors

DC servo motors are preferred for low-voltage, portable, or small-scale systems. They provide smooth movement and are easy to control with basic circuitry. DC servo motors are common in small robotic systems, toys, actuators, and learning projects that prioritize simplicity.

Brushless Servo Motors

Brushless servo motors eliminate physical brushes, improving lifespan and reducing maintenance. They provide high efficiency, fast acceleration, and precise movement, making them ideal for drones, medical equipment, and high-performance robotics requiring consistent operation.

Brushed Servo Motors

These are simpler and more affordable designs using carbon brushes to transfer current. They are commonly used in lower-demand applications that do not require long continuous duty, such as lightweight motion projects and hobby robotics.

Positional Rotation Servo Motors

These servos move within a fixed angle range, typically 0° to 180°. They are heavily used in robotic arms, sensor positioning mechanisms, and applications requiring controlled but limited rotation.

Continuous Rotation Servo Motors

Instead of angle control, these servos provide continuous rotational movement in both directions. They are often used in mobile robots, conveyor mechanisms, and motion systems that require ongoing rotation rather than position control.

Linear Servo Motors

Linear servo motors convert rotational movement into straight-line motion through a specialized mechanism. They support precise linear displacement, making them ideal for CNC machines, laboratory automation, and precision industrial equipment.

FAQs

What is the main purpose of a servo motor?

A servo motor provides accurate control of speed, torque, and position using a closed-loop feedback system for precision movement.

Which servo motor type is used in robotics?

Brushless servo motors and positional rotation servos are commonly used due to their accuracy, fast response, and long operational life.

How does feedback work in a servo motor?

A sensor such as an encoder or potentiometer constantly monitors the motor’s position or speed and adjusts it in real time to match the input command.

Are servo motors energy efficient?

Yes. Many modern servo motors use optimized control electronics and brushless designs to reduce power consumption, especially during variable workloads.

Where are linear servo motors used?

They are often used in CNC equipment, automated laboratory systems, and precision instruments requiring controlled linear displacement.

Conclusion

Servo motor types form the foundation of modern motion control systems across robotics, automation, manufacturing, healthcare, and scientific industries. They exist because precision, feedback, and controlled movement are essential for accuracy and safety in today’s technology. The evolution of electronics and digital drives continues to enhance servo performance, allowing these motors to achieve higher torque, improved speed accuracy, and greater reliability. Understanding the different servo motor types helps users choose the best system for technical applications while ensuring safety, performance, and alignment with evolving industry standards.